Product Finishing Functionalities

The Engineering uses the Product Finishing type functionalities to perform finishing activities in products such as magazine. Book etc. All components that aggregate other components are considered products. For example, cover + book compose the magazine; without those components, there are no magazine. Therefore, the magazine is an aggregation component. The Product Finishing functionalities are:

1005 – Stitching Machine

1007 – Gatherer

1011 – Gatherer (Perfect Bind)

1014 – Covering Machine (Perfect Bind)

1026 – Inserting Machine

1027 – Sewing

1029 – Wire-o

1030 – Spiral

1032 – Glue in Line

1035 – Component Kitting

1051 – Waste stripping (Block)

1055 – Paster

1056 – Wrap Product

Find bellow the detailed information of each functionality:

1005 – Stitching Machine

|

Use |

|

|

The Engineering uses the 1005 – Stitching Machine functionality for applying the stitching wire on a product that already has a cover and book block. The stitching functionality is usually combined with other functionalities in order to perform all the functions of a stitching machine, since the same machine can, for example, collate and apply the stitching wire. In this case, the 1007 – Collector functionality must also be linked to the stitching functionality. For more information on the relationships between the functionalities in the Production Group, refer to "Production Group Inputs.” |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1002 – Compound component 1007 – Stitching Wire |

1002 – Compound component |

|

Functionality Activation |

|

|

The following Specification Characteristic Types Classes activate the 1005 - Stitching Machine functionality: Saddle Stitching Spine Simplified Product Finishing For more information, refer to “Specification Characteristic Types – Saddle Stich – Wire Stitched.” and “Specification Characteristic Types – Simplified Product Finishing” in iQuote User Guide – Product Specification Records. |

|

|

Machines that Commonly Use the Functionality |

|

|

Saddle Stitching Machines Handling |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Stitching wire – (represented by the input components 1007 – Stitching Wire). The raw materials are linked in the Specification Characteristic Class that activates the functionality. For more information, refer to "Specification Characteristic Types – Saddle Stich – Wire Stitched" in iQuote User Guide – Product Specification Records. For more information, refer to “Wire Stitching.” |

|

Linking this functionality to a Production Group

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

Field |

Description |

|

Sticthes |

Indicates if the number of wire stitches applied will be restricted. |

|

Quantity |

Number of stitches the functionality can apply at a time. It is possible to set the number of stitches in the product in the product specification in the Saddle Stitch – Wire Stitched class. If the amount reported is higher than that recorded in functionality, the Engineering will not be calculated. This field will be displayed only if the Wire Stitches option is enabled. |

|

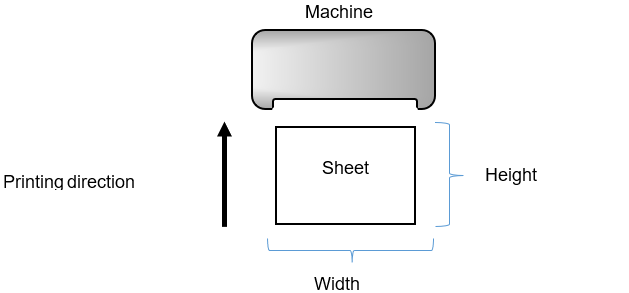

Input Format |

Indicates if the minimum and maximum size for the input component will be restricted. |

|

Minimum (WxH) |

Input component’s minimum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled.

|

|

Maximum (WxH) |

Input component’s maximum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled. |

|

Thickness |

Indicates if the thickness validation will be used for the input component. |

|

Minimum |

Minimum thickness to be considered as a restriction. This validation will be applyied to the compound component type of input component. This field will be displayed only if the Thickness option is enabled. |

|

Maximum |

Maximum thickness to be considered as a restriction. This validation will be applyied to the compound component type of input component. This field will be displayed only if the Thickness option is enabled. |

Click Confirm. When finished, click Save and Close.

1007 – Gatherer

|

Use |

|

|

The Engineering uses the 1007 – Gatherer functionality for performing the following processes: Gathering components such as a cover and several signatures. Pre gathering components when the number of input components is greater than the number of pockets in the machine such as in a stitching machine. Gathering is the process of joining components and positioning them one inside the other, as shown in the following figure.

The gathering functionality is usually combined with other since the same machine can, for example, gather and apply the stitching wire. In this case, the 1005 – Stitching Machine functionality must be linked also to the gathering functionality in the Production Group. For more information on the relatioships between the functionalities in the Production Group, refer to "Production Group Inputs.” |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1001 – Sheet 1002 – Compound component 1013 – Irregular Sheet/ carton 1014 – Component Coupling (Kit) 1019 – Collecting (page division) 1022 – Sheet (handouts) |

1002 – Compound component |

|

Functionality Activation |

|

|

The following Specification Characteristic Types classes activate 1007 – Gatherer functionality: Spine – Loose (Collected only) Simplified Product Finishing Saddle Stiching Spine For more information, refer to “Specification Characteristic Types – Spine – Loose (Gathered only).”, “Specification Characteristic Types – Simplified Product Finishing.” and “Specification Characteristic Types – Saddle Stiching Spine” in iQuote User Guide – Product Specification Records. The Engineering itself can activate the 1007 – Gatherer functionality when the functionality 1050 – Block Adapter is activated by other processes. For more information, refer to “Functionality 1050 – Block Adapter.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Gathering Machines. Wire stitching Machines. Handling. |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Does not have it. |

|

Linking this functionality to a Production Group

Note: If one of the input components is a book block with many pages, it will be necessary to select the component 1019 – Collecting (page division) as an input functionality.

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

|

Description |

|

Collection Station |

Indicates the number of collection stations of the machine will be restricted. |

|

Number of stations |

Number of stations available to receive components that will be collated such as signatures, covers, folders, etc. If this number is greater than the number of stations, the Engineering calculate other machine entries until all components are collated. When making filters to validate the amount of components in the pockets, the maximum limit considered is always the number of pockets and not the number of signatures. This field is displayed only if the Collection Station is enabled. |

|

Separate pre gathering |

Indicates whether the pre gathering will be separated into different activities for each entry. |

|

Has manual entry |

The manual input will be used if more than one entry are necessary to gather all of the product’s signatures, as when there are more signatures than pockets in the gatherer. |

|

Has cover station |

Indicates if the gatherer has a specific entry for the cover. By checking this option the cover will not occupy a gathering pocket. |

|

Stations for 4-pages signatures without folding |

Indicates if the gatherer is tower type, that is, if only not folded 4-pages will be gathered. |

|

Gathering Flap |

Indicates if the gathering flap margin value is enabled. This option should be kept enabled for the gathering functionality. |

|

Value |

Margin value to be applied to the component’s collecting flap. The collecting flap position will be determined by the folding scheme. For more information, refer to "Folding Schemes.” This field is displayed only if the Collecting Flap option is enabled. |

|

Minimum |

Minimum margin value to be considered as component’s gathering flap. This value indicates the minimum margin to be applied to the flap, if the margin is manually edited in the Engineering. This field is displayed only if the Gathering Flap option is enabled. In order to make it possible to manually edit this value in the Engineering, leave this field blank or fill it with 0. |

|

Maximum |

Maximum margin value to be considered as component’s gathering flap. This value indicates the maximum margin to be applied to the flap if the margin is manually edited in the Engineering. This field is displayed only if the Gathering Flap option is enabled. In order to make it possible to manually edit this value in the Engineering, leave this field blank or fill it with 0. |

|

Input Format |

Indicates if the minimum and maximum size for the input component will be restricted. |

|

Minimum (WxH) |

Input component’s minimum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled.

|

|

Maximum (WxH) |

Input component’s maximum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled. |

|

Thickness |

Indicates if the thickness validation will be used for the input component. Note: For the engineering component classes “Kit” and “Provided” the thickness is not validated in the system. |

|

Minimum |

Minimum thickness to be considered as a restriction. This validation will be applied to the sheet type of input component. This field will be displayed only if the Thickness option is enabled. |

|

Maximum |

Maximum thickness to be considered as a restriction. This validation will be applied to the sheet type of input component. This field will be displayed only if the Thickness option is enabled. |

Click Confirm. When finished, click Save and Close.

1011 – Collector (Perfect Bind)

|

Use |

|

|

The Engineering uses the 1011 – Collector (Perfect Bind) functionality for performing the following processes: Collecting of components such as several signatures, posters, etc. Pre collecting of components when the number of input components is greater than the number of pockets in the machine such as in a perfect biding machine. Collecting is the process of putting components together.

The collecting functionality is usually combined with others since the same machine can, for example, gather and apply the cover. In this case, the 1014 – Cover machine (Perfect Bind) functionality must be linked also to the collecting functionality in the Production Group. For more information on the relationships between the functionalities in the Production Group, refer to "Production Group Inputs.” |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1001 – Sheet 1002 – Compound component 1013 – Irregular Sheet/ carton 1014 – Component Coupling (Kit) 1019 – Collecting (page division) 1022 – Sheet (handouts) |

1002 – Compound component |

|

Functionality Activation |

|

|

The following Specification Characteristic Types classes activate 1011 – Collector (Perfect Bind) functionality: Perfect Binding – Hardcover Perfect Binding – Glued Simplified Product Finishing For more information, refer to “Specification Characteristic Types – Perfect Binding – Hardcover”, “Specification Characteristic Types – Perfect Binding – Glued” and “Specification Characteristic Types – Simplified Product Finishing” in iQuote User Guide – Product Specification Records. The Engineering itself can activate the 1011 – Collector (Perfect Bind) functionality when the functionality 1050 – Block Adapter is activated by other processes. For more information, refer to “Functionality 1050 – Block Adapter.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Collecting Machines. Perfect Binding Machines. Handling |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Does not have it. |

|

Linking this functionality to a Production Group

Note: If one of the input components is a book block with a signature format, it will be necessary to select the component 1019 – Collecting (page division) as an input functionality.

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

Field |

Description |

|

Collecting Station |

Indicates the number of collection stations of the machine will be restricted. |

|

Number of Inputs |

Number of stations available to receive components that will be collected such as signatures, covers, folders, etc. If this number is greater than the number of stations, the Engineering calculate other machine entries until all components are collected. The cover is not considered as a collecting component, because it will be used by 1014 – Cover machine (Perfect Bind) functionality to be attached to the book block. This field is displayed only if the Collection Station is enabled. |

|

Separate pre gathering |

Indicates whether the pre gathering will be separated into different activities for each entry. |

|

Simulate “come-and-go” |

Indicates if the option to allow the collection simulation using "Come and go" is enabled, also known as "First and last". For this to be possible it is necessary: The component to be printed on double To be the same component |

|

Has manual entry |

If it is necessary to use more than one entry to collect all the product’s signatures the manual feeding can be used. The signatures collected in the first entry must be manually placed into the machine at the second entry, so they don’t use a pocket. In this case, the Engineering will be calculated with more than one entry. |

|

Gathering Flap |

Indicates if the gathering flap margin value is enabled. This option should be kept enabled for the collecting functionality. |

|

Value |

Margin value to be applied to the component’s gathering flap. The collecting flap position will be determined by the folding scheme. For more information, refer to "Folding Schemes.” This field is displayed only if the Collecting Flap option is enabled. |

|

Minimum |

Minimum margin value to be considered as component’s collecting flap. This value indicates the minimum margin to be applied to the flap, if the margin is manually edited in the Engineering. This field is displayed only if the Collecting Flap option is enabled. In order to make it possible to manually edit this value in engineering, leave this field blank or fill it with 0. |

|

Maximum |

Maximum margin value to be considered as component’s collecting flap. This value indicates the maximum margin to be applied to the flap if the margin is manually edited in the Engineering. This field is displayed only if the Collecting Flap option is enabled. In order to make it possible to manually edit this value in engineering, leave this field blank or fill it with 0. |

|

Input Format |

Indicates if the minimum and maximum size for the input component will be restricted. |

|

Minimum (WxH) |

Input component’s minimum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled.

|

|

Maximum (WxH) |

Input component’s maximum format in which W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled. |

|

Thickness |

Indicates if the thickness validation will be used for the input component. |

|

Minimum |

Minimum thickness to be considered as a restriction. This validation will be applied to the sheet type of input component. This field will be displayed only if the Thickness option is enabled. |

|

Maximum |

Maximum thickness to be considered as a restriction. This validation will be applied to the sheet type of input component. This field will be displayed only if the Thickness option is enabled. |

|

Pre finishing |

Indicates if the pre finishing will be separated into different activities for each entry. |

|

Simulate case bound component (it limits the folding scheme) |

Indicates if the system will simulate a component with 2 finishings in the same machine entry. For example, if the book block will be shared between two products, one being case bound (sewn) and the other perfect bound (glued):

Typically a case bound product has a flap for collecting and a perfect bound product does not. The signatures can not be produced in one single entry if they do not have the same size, margins etc. Therefore, in order to be possible to the component to be produced in only one entry is required that: All functionalities in 1011 – Collector involved in the calculation have the Simulate component milled and sewn in the same print input (limit the fold scheme) enabled. No gathering flap may be enabled in the sewing machine and in the perfect biding machine. The same milling value is applied in the case biding and the perfect binding processes. The folding schemes that should be selected for the signatures, can not be have the parameters "Do not simulate Saddle Stitch (station)/ Sewn spine” and “Do not simulate Perfect biding” enabled. For more information, refer to "Adding Folding Schemes. |

Click Confirm. When finished, click Save and Close.

1014 – Cover machine (Perfect Bind)

|

Use |

|

|

The Engineering uses the 1014 – Cover machine (Perfect Bind) functionality for applying cover to perfect bound products. The book block must have been previously gathered to receive a cover. For this reason, usually this functionality can also be linked to the 1011 – Gatherer (Perfect Bind) functionality. For more information on the relatioships between the functionalities in the Production Group, refer to "Production Group Inputs.” |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1001 – Sheet 1002 – Compound component 1006 – Glue 1013 – Irregular Sheet/ carton |

1002 – Compound component |

|

Functionality Activation |

|

|

The following Specification Characteristic Types classes activate 1014 – Cover machine (Perfect Bind) functionality: Perfect Binding – Hardcover Perfect Binding – Glued Simplified Product Finishing For more information, refer to “Specification Characteristic Types – Perfect Binding – Hardcover.”, “Specification Characteristic Types – Perfect Binding – Glued.” and “Specification Characteristic Types – Simplified Product Finishing” in iQuote User Guide – Product Specification Records. |

|

|

Machines that Commonly Use the Functionality |

|

|

Perfect Bind Machines Handling |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Glue (represented by the input component 1006 – Glue). The raw materials are linked to the Specification Characteristic classes that activates the functionality. For more information, refer to “Specification Characteristic Types – Perfect Binding – Glued” in iQuote User Guide – Product Specification Records. For more information on recording this raw material, refer to “Glue.” |

|

Linking this functionality to a Production Group

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

Field |

Description |

|

Milling area |

Indicates if the milling margin will be applied. This option should be kept enabled for this functionality. |

|

Size |

Size of the milling margin applied to the signature’s spine, as shown in the area marked in green. This field is displayed only if the Milling area options enabled.

|

|

Input Format |

Indicates if the minimum and maximum size for the input component will be restricted. This option should be kept enabled for this functionality. |

|

Minimum (WxH) |

Input component’s minimum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled.

|

|

Thickness |

Indicates if the thickness validation will be used for the input component. |

|

Minimum |

Minimum thickness to be considered as a restriction. This field will be displayed only if the Thickness option is enabled. |

|

Maximum |

Maximum thickness to be considered as a restriction. This field will be displayed only if the Thickness option is enabled. |

|

Lateral glue area |

Indicates if the option to determine the size of the lateral glue area is enabled |

|

Size |

Value for the lateral glue area size to be considered for calculating the glue. When filling this field with 3, the Engineering will apply 3 mm on each of the cover 2 sides. For more information on glue consumption calculation, refer to "Glue."

This field is displayed only if the Lateral glue area option is enabled. |

|

Glue Types |

Indicates if the option to determine the glue types that can be used in this process is enabled. When this option is selected, it is necessary to choose the appropriate recorded glue types. If no glue is selected, the Engineering will not be calculated. For more information on recording glue types, refer to "Glue types." |

|

Glue Consumption Reduction |

Indicates if the glue consumption reduction option is enabled. This reduction is usually applied to the pre glue process. |

|

Percentage |

Percentage that reduces the glue consumption (in g/m2) set in the glue used. For more information on glue consumption calculation, refer to "Glue.” This field is displayed only if the Glue Consumption Reduction is enabled. |

Click Confirm. When finished, click Save and Close.

1026 – Inserting machine

|

Use |

|

|

The Engineering uses the 1026 – Inserter functionality for inserting loose components inside other products or product’s packages. |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

All recorded Engineering components |

1002 – Compound component 1009 – Package |

|

Functionality Activation |

|

|

The following Aggregation and the Packaging Specification Characteristic Types activate 1026 – Inserting machine functionality, as long as they have the Uses the aggregation inserted option set in the Composition Types area, which can be accessed in the appropriate characteristic details screen. The Specification Characteristics with this configuration are: Aggregation Type Classes: Perfect Binding – Glued Perfect Binding – Hardcover Saddle Stich – Wire stiched Spine – Wire-o Spine – Spiral Simplified Product Finishing Package Type Classes: Package – Shrink Package – Bag For more information, refer to “Specification Characteristic Types.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Inserting Machines Handling |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Does not have it. |

|

Linking this functionality to a Production Group

This functionality does not have any additional information. Simply click Confirm then click Save and Close.

1027 – Sewing

|

Use |

|

|

The Engineering uses the 1027 – Sewing functionality for sewing components already gathered. This functionality can be used together with other functionalities such as the 1011 – Collector functionality. For more information on linking functionalities in the Production Group, refer “Production Group Inputs.” |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1002 – Compound component |

1002 – Compound component |

|

Functionality Activation |

|

|

The following Specification Characteristic Types activate the 1027 – Sewing functionality Perfect Binding – Glued Perfect Binding – Hardcover In order to the Engineering to activate the sewing functionality it is necessary that the Sewn option is enabled for the product, in the appropriate Specification Characteristic. For more information, refer to “Specification Characteristic Types – Perfect Binding – Glued.” and “Specification Characteristic Types – Perfect Binding – Hardcover.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Sewing Machines. |

|

|

Functionality Restriction |

|

|

The components must have been previously gathered. In order to do that, it is necessary to record the 1011 – Collector functionality, in the same Production Group or not. |

|

|

Functionality’s Default Raw Material |

|

|

This functionality does not have a default raw material. But it is possible to calculate the raw material in the Engineering using the customized raw material function. For more information on recording customized raw materials, refer to “Production Group Customized Raw Material.” |

|

Linking this functionality to a Production group

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

Field |

Description |

|

Collecting Flap |

Indicates if the collation flap margin value is enabled. This option should be kept enabled for the collecting functionality. |

|

Value |

Margin value to be applied to the component’s collecting flap. The collecting flap position will be determined by the folding scheme. For more information, refer to "Folding Schemes.” This field is displayed only if the Collecting Flap option is enabled. |

|

Minimum |

Minimum margin value to be considered as component’s collecting flap. This value indicates the minimum margin to be applied to the flap, if the margin is manually edited in the Engineering. This field is displayed only if the Collecting Flap option is enabled. In order to make it possible to manually edit this value in engineering, leave this field blank or fill it with 0. |

|

Maximum |

Maximum margin value to be considered as component’s collecting flap. This value indicates the maximum margin to be applied to the flap if the margin is manually edited in the Engineering. This field is displayed only if the Collecting Flap option is enabled. In order to make it possible to manually edit this value in engineering, leave this field blank or fill it with 0. |

|

Input Format |

Indicates if the minimum and maximum size for the input component will be restricted. |

|

Minimum (WxH) |

Input component’s minimum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled.

|

|

Maximum (WxH) |

Input component’s maximum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled. |

Click Confirm. When finished, click Save and Close.

1029 – Wire-o

|

Use |

|

|

The Engineering activates the 1029 – Wire-o functionality for applying wire-o in a product consisting of cover and book block. The wire-o functionality is usually combined with other functionalities for performing all functions of a wire-o machine, since the same machine can, for example, perforate the substrate and apply the wire-o. In this case, the functionality 1028 – Perforator (block) must also be linked to the wire-o functionality. For more information, refer to "Production Group Inputs.” |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1002 – Compound component 1025 – Wire-o |

1002 – Compound component |

|

Functionality Activation |

|

|

The Wire-o Spine class of Specification Characteristic Type activates the 1029 – Wire-o functionality. For more information, refer to "Specification Characteristic Type – Spine – Wire-o.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Wire-o application machines. Handling. |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Wire-o (represented by the input component 1025 – Wire-o). The raw materials are linked to the class Specification Characteristic that activates the functionality. For more information, refer to "Specification Characteristics Types – Spine – Wire-o.” For more information on recording raw materials, refer to "Wire-o.” |

|

Linking this functionality to a Production Group

This functionality does not have any additional information. Simply click Confirm then click Save and Close.

1030 – Spiral

|

Use |

|

|

The Engineering activates the 1030 – Spiral functionality for applying spiral in a product consisting of cover and book block. The spiral functionality is usually combined with other functionalities for performing all functions of a spiral machine, since the same machine can, for example, perforate the substrate and apply the spiral. In this case, the functionality 1028 – Perforator (block) must also be linked to the spiral functionality. For more information, refer to "Production Group Inputs.” |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1002 – Compound component |

1002 – Compound component |

|

Functionality Activation |

|

|

The Spiral Spine class of Specification Characteristic Type activates the 1030 – Spiral functionality. For more information, refer to "Specification Characteristic Type – Spine – Spiral.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Spiral application machines. Handling. |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

This functionality does not have a default raw material. But it is possible to calculate the raw material in the Engineering using the customized raw material function. For more information on recording customized raw materials, refer to “Production Group Customized Raw Material.” |

|

Linking this functionality to a Production Group

This functionality does not have any additional information. Simply click Confirm then click Save and Close.

1032 – Glue In-line

|

Use |

|

|

The Engineering uses the 1032 – Glue In-line functionality for applying glue in the following situations: In-line in the webfed press, applying total glue line on components that are the final product. In-line in the webfed press, applying patial glue line on components that have folding schemes requiring a partial glue lines before goingo to the wire stitching process. This functionality is typically used together with the webfed printer. Therefore, it is necessary to add the 1001 – Webfed Offset Press functionality and link the functionalities. For more information, refer to “Functionality 1001 – Webfed Offset.” For more information on how to link functionalities in Production Group, refer to "Production Group Inputs.”. |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1001 – Sheet 1006 – Glue |

1001 – Sheet |

|

Functionality Activation |

|

|

The 1032 - Glue In-line functionality will be activated: By the Saddle Sticth – Glue in-line class of Specification Characteristic Type. For more information, refer to "Specification Characteristic Types – Saddle Sticth – Glue in-line.” By the wire stitching process, when the component has a folding scheme requiring a partial glue line application. For more information, refer to "Folding schemes.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Webfed presses. |

|

|

Functionality Restriction |

|

|

To be able to use this functionality, it is necessary that the folding scheme used be set with glue line points. For more information, refer to "Folding schemes.” If the functionality is activated by the Saddle Sticth – Glue in-line Specification Characteristic, it is necessary that the component with this characteristic be the final product, that is, the component’s number of pages must be the same as the product’s total number of pages. In this type of process, the component will not go through any more finishing processes (wire stitching or perfect biding). |

|

|

Functionality’s Default Raw Material |

|

|

Glue (represented by the input component 1006 – Glue). In glue record, it is possible to determine the glues that can be used to perform this process. For more information, refer "Glue.” |

|

Linking this functionality to a Production Group

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

Field |

Description |

|

Glue Area Width |

Indicates if an option to inform the glue area width will be enabled. This option should be kept enabled for this functionality. |

|

Size |

The value set in this field will define the glue line width in any position according to the folding scheme, as shown in the area marked in green.

This value is used in calculating glue consumption using the formula: Glue line weight (kg) = Cutoff (meters) x Glue area width (meters) x Number of nozzles x Total cycles x (Consumption (g/m2)/1,000). Where: Number of nozzles – Correspond to the Height factor or Width factor fields in the folding scheme record. For more information, refer to “Folding schemes.” This field will be displayed only if the Glue Area Width option is enabled. |

Click Confirm. When finished, click Save and Close.

1035 – Component kitting

|

Use |

|

|

The Engineering uses the 1035 – Component kitting functionality for grouping different components in a kit such as a magazine, a CD and a brochure, packed in a promotional box. |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

All recorded Engineering components |

1014 – Component kitting |

|

Functionality Activation |

|

|

The Component kitting class of Specification Characteristic Type activates the 1035 – Component kitting functionality. For more information, refer to “Specification Characteristic Types – Component kitting” in iQuote User Guide – Product Specification Records. |

|

|

Machines that Commonly Use the Functionality |

|

|

Handling. |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Not applicable. |

|

Linking this functionality to a Production Group

This functionality does not have any additional information. Simply click Confirm then click Save and Close.

1056 – Wrap product

|

Use |

|

|

The Engineering uses the 1056 – Wrap product functionality for wrapping products. This characteristic is typically used when a product such as a hard cover book, has a dust jacket which is not glued to it. |

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

All recorded Engineering components |

1002 – Compound component 1009 – Package |

|

Functionality Activation |

|

|

The following Aggregation and Specification Characteristic Types activate 1056 – Wrap product functionality, as long as they have the Uses the aggregation Wrapped option set in the Composition Types area, which can be accessed in the appropriate characteristic details screen. The Specification Characteristics with this configuration are: Aggregation Type Classes: Perfect Binding – Glued Perfect Binding – Hardcover Saddle Sticth – Wire sticthed Simplified Product Finishing Spine - Loose (Gathered only) Spine – Wire-o Spine – Spiral For more information, refer to “Specification Characteristic Types.” |

|

|

Machines that Commonly Use the Functionality |

|

|

Handling Wrapping machines |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Not applicable. |

|

Linking this functionality to a Production Group

This functionality does not have any additional information. Simply click Confirm then click Save and Close.

1051 – Waste stripping (Block)

|

Use |

|

|

The Engineering activates the 1051 – Waste stripping (Block) functionality for stripping the blocks. The block stripping process consists of separating blocks that are made and glued one over the other in only one gluing process. |

|

|

Before stripping |

After stripping |

|

|

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1002 – Compound component |

1002 – Compound component |

|

Functionality Activation |

|

|

The Engineering activates the 1051 – Waste stripping (Block) functionality for stacking several blocks to be printed and glued together in order to optimize various processes using larger components. |

|

|

Machines that Commonly Use the Functionality |

|

|

Stripping machine. |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Does not have it. |

|

Linking this functionality to a Production Group

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

Field |

Description |

|

Thickness |

Indicates if the thickness validation will be used for the input component. This option must be kept enabled for this functionality. |

|

Minimum |

Minimum thickness to be considered as a restriction. This validation will be applied to the sheet type of input component. This field will be displayed only if the Thickness option is enabled. |

|

Maximum |

Maximum thickness to be considered as a restriction. This validation will be applied to the sheet type of input component. This field will be displayed only if the Thickness option is enabled. |

Click Confirm. When finished, click Save and Close.

1055 – Paster

|

Use |

|

|

The Engineering activates the 1055 – Paster functionality for pasting the cover to a cardboard. This process is usually performed when a wire-o or spiral product has a hard cover.

|

|

|

Engineering Components Types Used |

|

|

Inputs |

Outputs |

|

1001 – Sheet 1006 – Glue 1013 – Irregular sheet/ Carton |

1001 – Sheet |

|

Functionality Activation |

|

|

The Pasting class of Specification Characteristic Type activates the 1055 – Paster functionality. For more information, refer to “Specification Characteristic Types – Pasting.” This functionality can also be activated when a Area component has its format linked to the cover. Only the Sheet and Handout formats will be considered for activating this functionality. |

|

|

Machines that Commonly Use the Functionality |

|

|

Plaster Machines. |

|

|

Functionality Restriction |

|

|

Does not have it. |

|

|

Functionality’s Default Raw Material |

|

|

Glue (represented by the input component 1006 – Glue). On the Glue record it is possible to define what glues may be used for this procees. For more information, refer to “Glue.” |

|

Linking this functionality to a Production Group

When adding this functionality to a production group, the system will display a window for you to configure the functionality further. Complete the fields in this window as described below:

|

Field |

Description |

|

Pasting area/ endpage |

Indicates if the option to determine the cardboard and endpage reduction is enabled. This option will be considered only for the area of components that have the Pasted Component class of Specification Characteristic Type and are linked to the cover. |

|

Reduction for area/endpage format calculation |

Reduction value to be applied to the cardboard and endpage, as shown by the yellow area. This option will be displayed only if the Pasting area/ endpage option is enabled.

There will be no reduction in the endpage inside lateral if the front and back covers is made in one piece and cut afterwards. |

|

Pasting cardboard and fold over |

Indicates if the option to define the default fold over margin and cardboard information will be enabled. |

|

Default fold over margin |

Margin value to be applied in the fold over. This field appears only if the Pasting cardboard and fold over option is enabled. |

|

Cardboard provided |

Indicates if the cardboard is provided by a third party. By enabling this option, the cost of the cardboard will not be added to the Estimate’s total cost. |

|

Input Format |

Indicates if the minimum and maximum size for the input component will be restricted. |

|

Minimum (WxH) |

Input component’s minimum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled.

|

|

Maximum (WxH) |

Input component’s maximum format in which the W value indicates the machine’s feeder width. If there are no sheets in this size or no sheet can be cut into this size, this functionality will not be considered by the Engineering. This field appears only if the Input format option is enabled. |

Click Confirm. When finished, click Save and Close.