Create Substrate Standards

A Substrate Standard defines the information shared by all substrates within a substrate group. For example, you can set up an Uncoated substrate standard to specify the same density for all uncoated substrates. Refer to the Create Substrate Groups topic in this guide for more information.

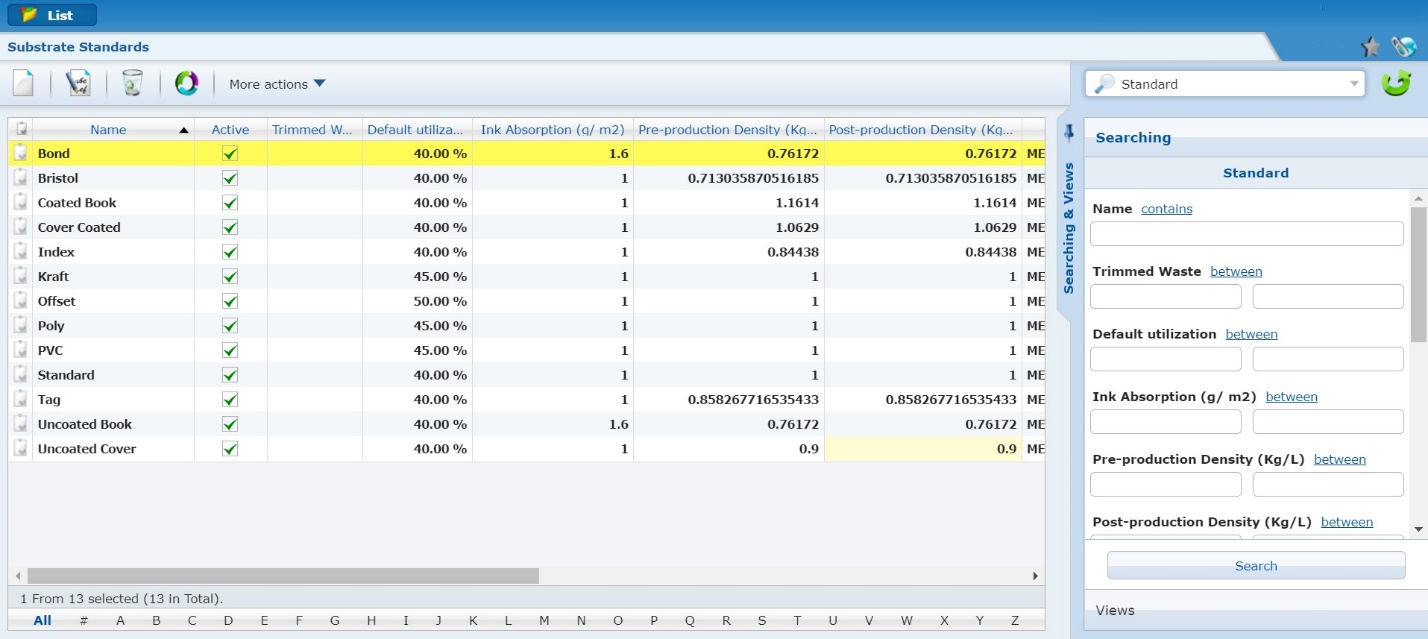

- Navigate to Sales > Records > iQuote > Engineering > Substrate Standards. The Substrate Standards screen opens with a list of Substrate Standard records.

- Do one of the following:

- To create a new substrate standard, click New.

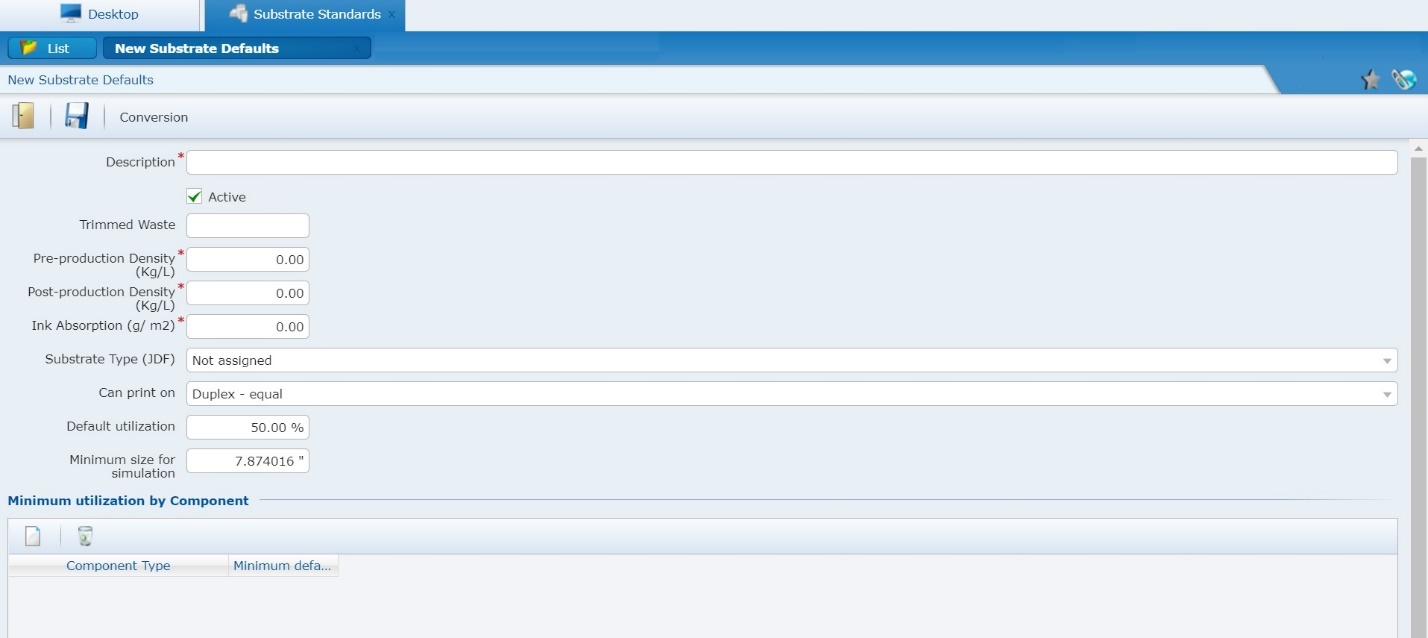

The New Substrate Defaults screen opens.

- To modify an existing substrate standard, double-click the row that contains the substrate standard you want to edit, or select the desired substrate standard and click Edit.

The Substrate Default screen opens, with the details of the substrate standard you selected.

- To delete an existing substrate standard, select the substrate standard you want to delete, click Delete, then click Yes to confirm the deletion.

The system removes the Substrate Standard record from the list on the Substrate Standards screen.

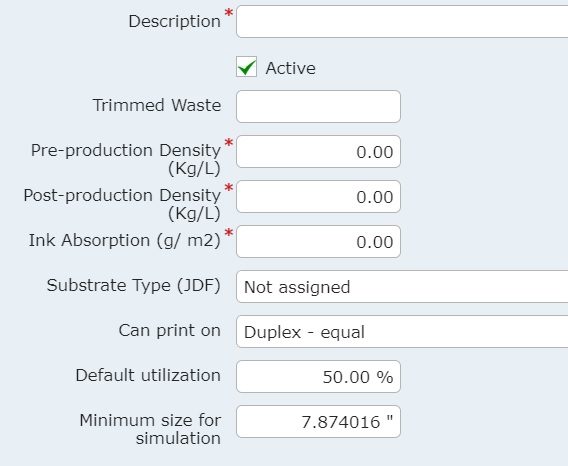

- Complete the following fields on the New or existing Substrate Defaults screen:

- In the Description field (required), enter a descriptive name for this substrate standard.

- Leave the Active check box selected to make this record available for use throughout the system.

- In the Trimmed Waste field, if necessary, enter the initial trim amount needed on the substrate edges before going into the press.

Tip: You can also use this field to enter the cut size of the substrate.

- In the Pre-production Density field (required), enter the density of the substrate before production.

- In the Post-production Density field (required), enter the density of the substrate after production.

Note: iQuote uses the values you enter in the Pre-production Density field and Post-production Density field to calculate the product weight for freight and other activities that are based on product weight.

- In the Ink Absorption field (required), enter the substrate’s ink absorption, in grams per square meter.

Note: iQuote uses the value you enter in this field to calculate ink needed for the substrate.

Tip: The following fields are optional.

- In the Substrate Type (JDF) field, select one of the available substrate types from the list. (Refer to the Create Substrate Types topic in this guide for more information.)

- In the Can Print On field, select whether you want this substrate to print on the front only or duplex.

- In the Default Utilization field, enter the percentage of this substrate you want to use in production.

- In the Minimum Size For Simulation field, enter the minimum size necessary for this substrate to be included in a simulation.

- If you want to define the minimum default utilization for specific substrate components, do all of the following in the Minimum Utilization By Component area. Otherwise, skip to step 5.

- To add a new minimum default utilization, click New (

).

).

A new row opens in the Minimum Utilization By Component area.

- From the drop-down list in the Component Type field of the new row in the Minimum Utilization By Component area, select the component type for which you want to set up a default minimum.

- In the Minimum Default Utilization field, enter the default minimum you want to apply to the selected component type.

- To delete an existing minimum default utilization record, select the desired record, click Delete (

), then click Yes to confirm the deletion

), then click Yes to confirm the deletion

- Click Save to save the record. The Substrate Standards screen refreshes, with the new or modified Substrate Standard record in the list.